Understand your business, and help you innovate.

The 30 years of experience in software design are no stranger to the success of the solutions we have proposed. Each project is above all considered as a true partnership, winning winner, or the efficiency and sustainability of the solution created are the first elements of motivation.

Here are some examples of what we have created:

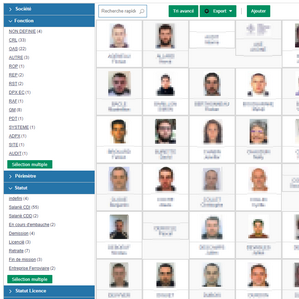

SECOT – SAFETY TOOL

Created in partnership with Ecorail Transport (Rail Freight), this software monitors the skills of train and OAS drivers. It meets the requirements of the European network.

Based on a business repository engine, this software is adaptable to all sectors of activity.

Monitoring employees' skills is one of the major levers for improving performance. Contact us to have a demonstration and study its portability to your sector of activity.

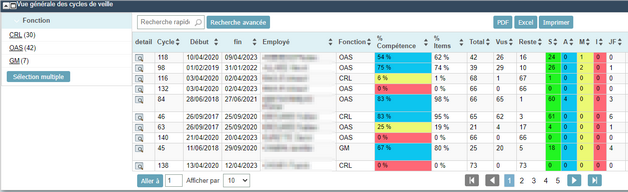

Employee Management

For each employee, skills management according to business reference, visits (medical, psychologist …), training and evaluations, monitoring of monitoring cycles and editing of official documents (authorization card, complementary certificate, RAC …)

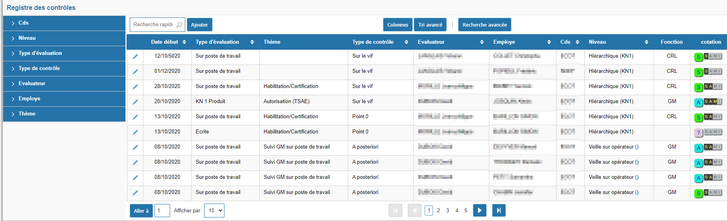

Registers and Statistics

Management of registers of evaluations, events, training, survey questionnaires, register of the general action plan… Statistical modules for monitoring monitoring cycles, 90-day deadlines, evaluations by control item.

Data exchanges

In order to synchronize and secure the information contained in the RailCube production software, a data exchange gateway was specifically developed to transfer the security data, which in turn was fed by the production data. Every night, these two software programs share their respective information.

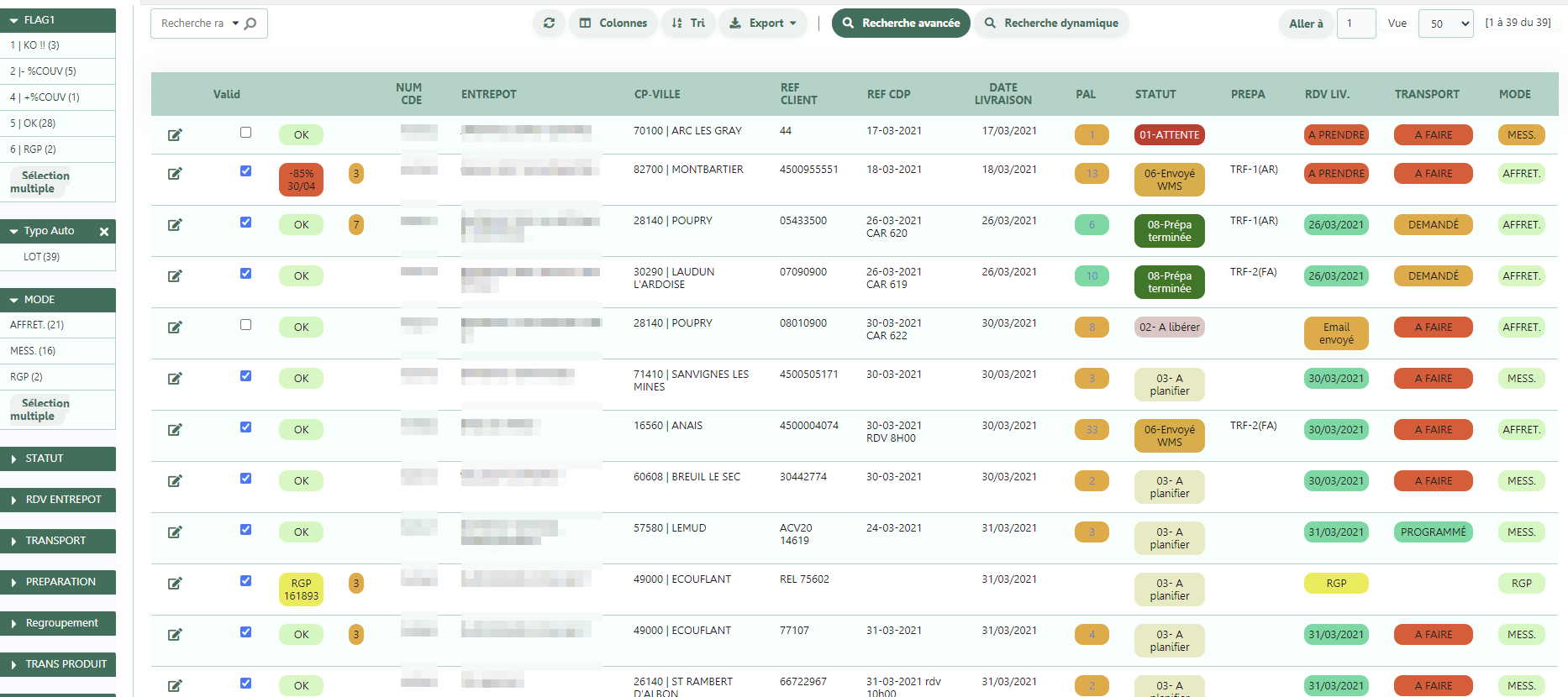

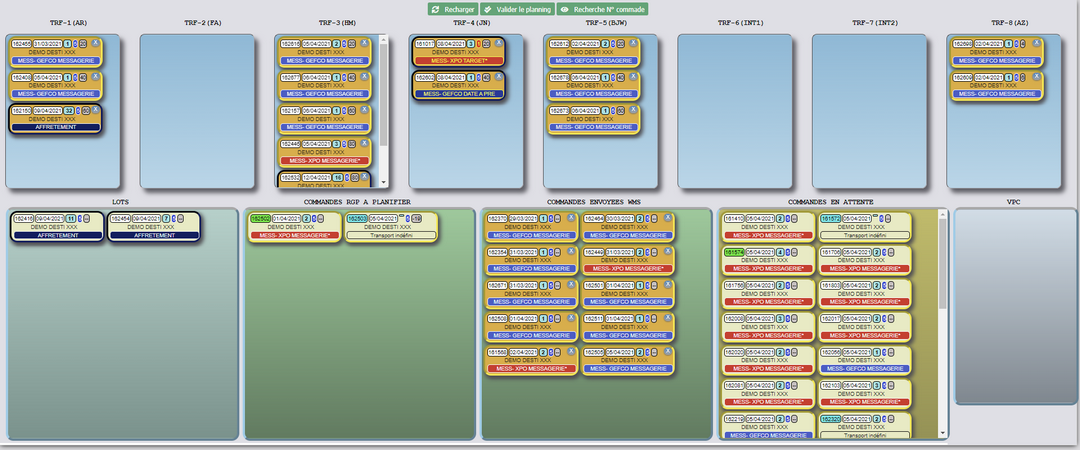

Production planning in

the OFFSET printing house

End-to-end load visibility.

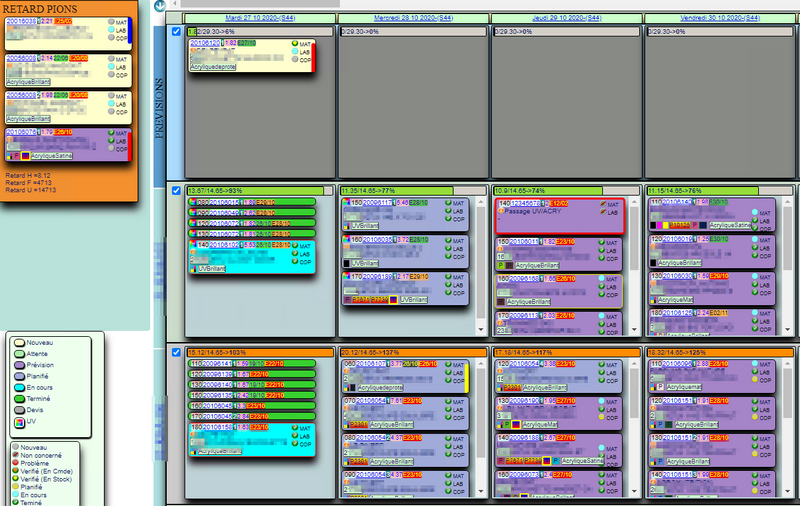

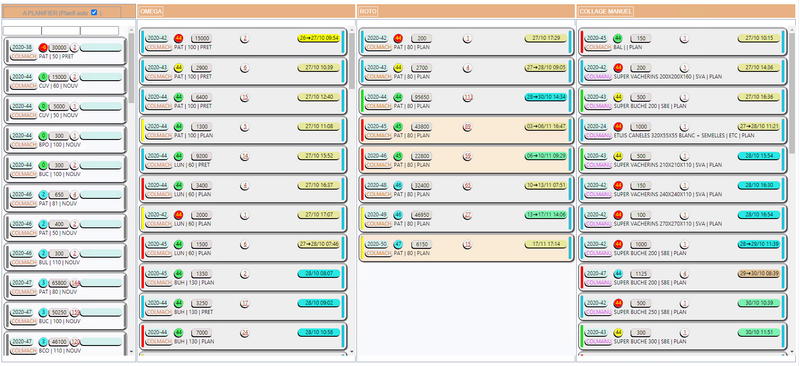

Schedule per day

Each rectangle (or pawn) here represents a manufacturing batch, with detailed information on the workload per machine per day. Each "pawn" carries several pieces of information including completion of the steps upstream of the stage concerned. The pawns can be moved directly with the mouse by a "drag and drop", which automatically updates the load rates and informs the schedules of the other steps.

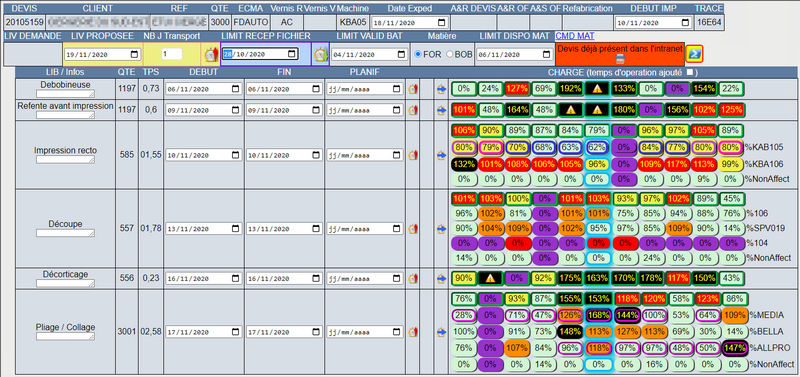

Visibility to Quotes

Thanks to the real-time update of production schedules, estimators see live load rates per day and per machine on each stage of production. The pre-planning carried out makes it possible to immediately announce the delivery time. This also makes it possible to know the deadline for making available the digital files intended to be printed as well as the deadline for signing the voucher to be drawn.

Stacking planning

This tool allows overflow (or finite load) scheduling. After the configuration of machine yields and operators, the definition of opening days and hours, it is possible to stack the manufacturing batches by machine and thus know the production time for each batch. The schedule is automatically updated in the event of a delay, which immediately highlights deadlines.

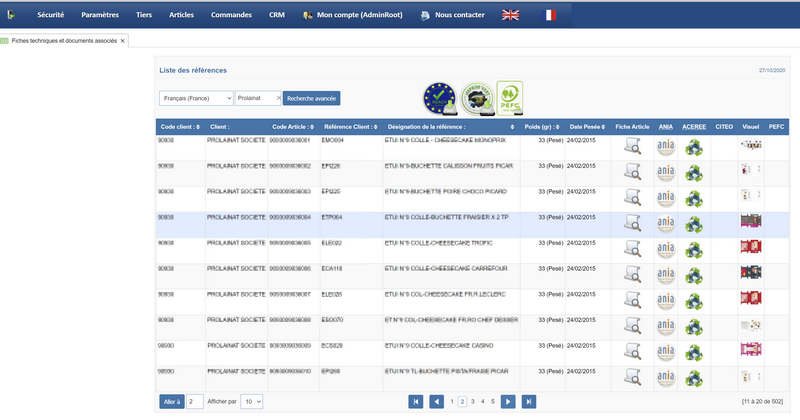

Extranet

This secure website allows communication with customers on the progress of their orders, the provision of files …

Customers can also download all technical and regulatory documents in PDF format. These PDF documents are automatically generated by the system once the batch production is complete and made available on the Extranet.

Data exchange with VOLUME (EDI)

All schedules, production monitoring, automated generation of data sheets (…), are derived from the data exchanged with the ERP Volume. And in the same way, via exchanges of XML files, production information is returned to VOLUME, such as production declarations, case weights, etc.